It is often said that people eat with their eyes. Chefs across the world have practiced for years to elegantly dress a plate and make a meal look appeasing. However, something more thrilling, and rather unconventional is making its way into the culinary arts. Yes! 3D Printed Food is what we’re talking about.

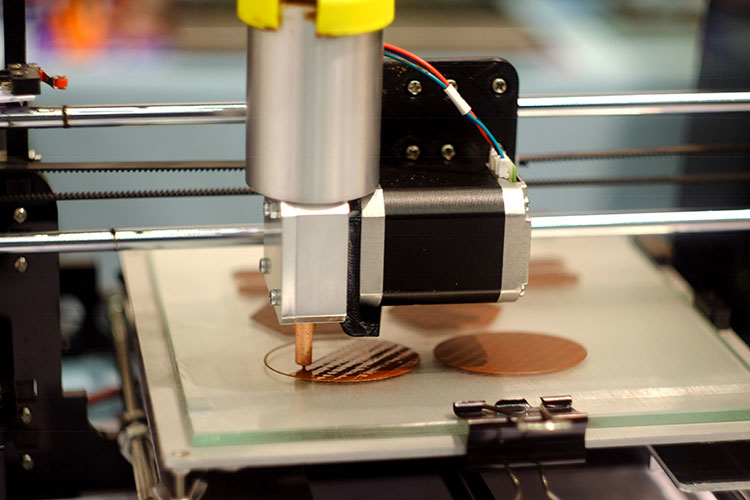

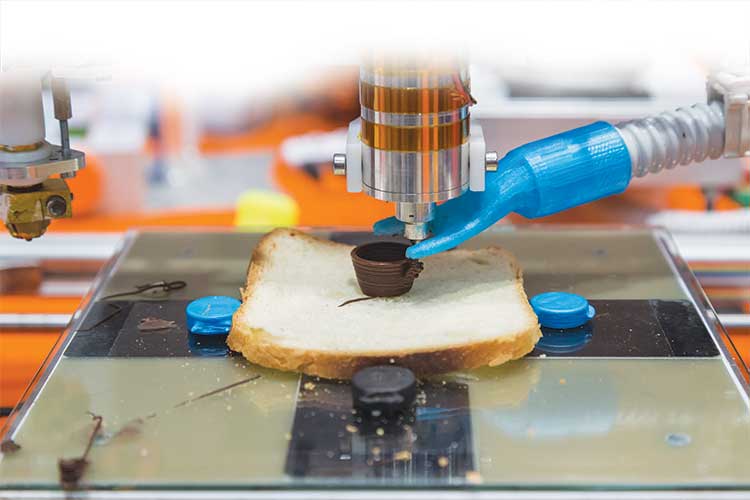

Using various additive manufacturing methods, 3D Printed food is achieved using a similar mechanism to that of a regular FDM 3D Printer. Viscous material added onto a surface, and Voilà! There you have it! This usually involves a food grade nozzle and some time. The 3D food printer builds the design one layer at a time as the nozzle deposits the printing material onto the surface.

3D printing of food is however, still in its infancy and has a long way to go. The kinds of food that can be 3D printed is heavily dependent on the technologies and materials present in the market. It is mostly used by pastry chefs and fine dining restaurants; this new style of food presentation is used to bring out details and intricacies to add a layer of depth and visual flair for a consumer.

Currently, the most common form used is called Extrusion Based Printing, where substances of a paste-like consistency are passed through the machine to produce a final object. Purées, ganache, mousses and other similar ingredients can be used. Although the current scope seems limited, there are endless possibilities that are already being put to the test when it comes to 3D printed food.

Other forms of 3D Food Printing involve Hot melt extrusion where the food material, such as chocolate, is melted slightly above its melting point and then released onto the surface where it quickly hardens. Binder Jetting and Selective laser sintering (SLS) are other forms of 3D food printing. Both use powdered food materials to produce the final result. In SLS, the powdered food material is bound by heat. However, Binder Jetting uses a liquid binder which forms a layer and is then sprayed with a layer of powder. Both these methods are known for their ability to create intricate structures and various textures.

Despite the excitement that surrounds 3D food printing, there are some drawbacks. Time and money are currently the two primary factors. A 3D food printer manufacturer named Choc Edge claims that it can take seven minutes to complete a simple six layered design. But a complex design would take more than 45 minutes to print. Apart from the time consumed, the cost of equipment and materials may also serve as a challenge, and the prep time and effort for food materials that are to be used can also be a setback.

Although 3D food printing has not achieved much commercial success just yet, there are benefits that make it a much more favourable method. 3D Food printers usually print the design and do not cook the food. The food is often cooked after the design has been printed. However, 3D printed food can be customised in shape, colour, nutrition, flavours, and texture. Not only does this make the food more visually appealing, which is a bonus for restaurants, but their ability to maintain absolute precision makes it boon for food at hospitals, as it can provide the option for “per patient customisation.”

3D printed food is also of great benefit to the health industry in terms of incentivising the consumption of traditionally avoided foods. When food looks amazing, the tummy starts growling! 3D printed food allows us to visually amaze using nutritious plants in paste like consistencies to make the food more likeable.

Additionally, reproducing 3D printed food by sharing your recipes is just as easy as you would do in the digital world. Just send the file over! As long as the person reproducing the food has the same ingredients, settings, and the right equipment, you have a copy of what you wanted to recreate.

Overall, the 3D Food Printing industry is on its journey to success. Just a couple of years ago 3D Printing as a whole was an alien technology to us, yet today we can find advanced resin 3D printers, capable of incredible levels of detail, for use in our very homes at affordable prices. With such consistent advancement in technology and mankind’s desire to achieve more, it is only a matter of time before 3D food printing make its way into homes, perhaps even replacing regular home cooking. Until then, keep an eye out for this new kid on the block and wow not just your tummies, but also your eyes!